STAMPING SHOP

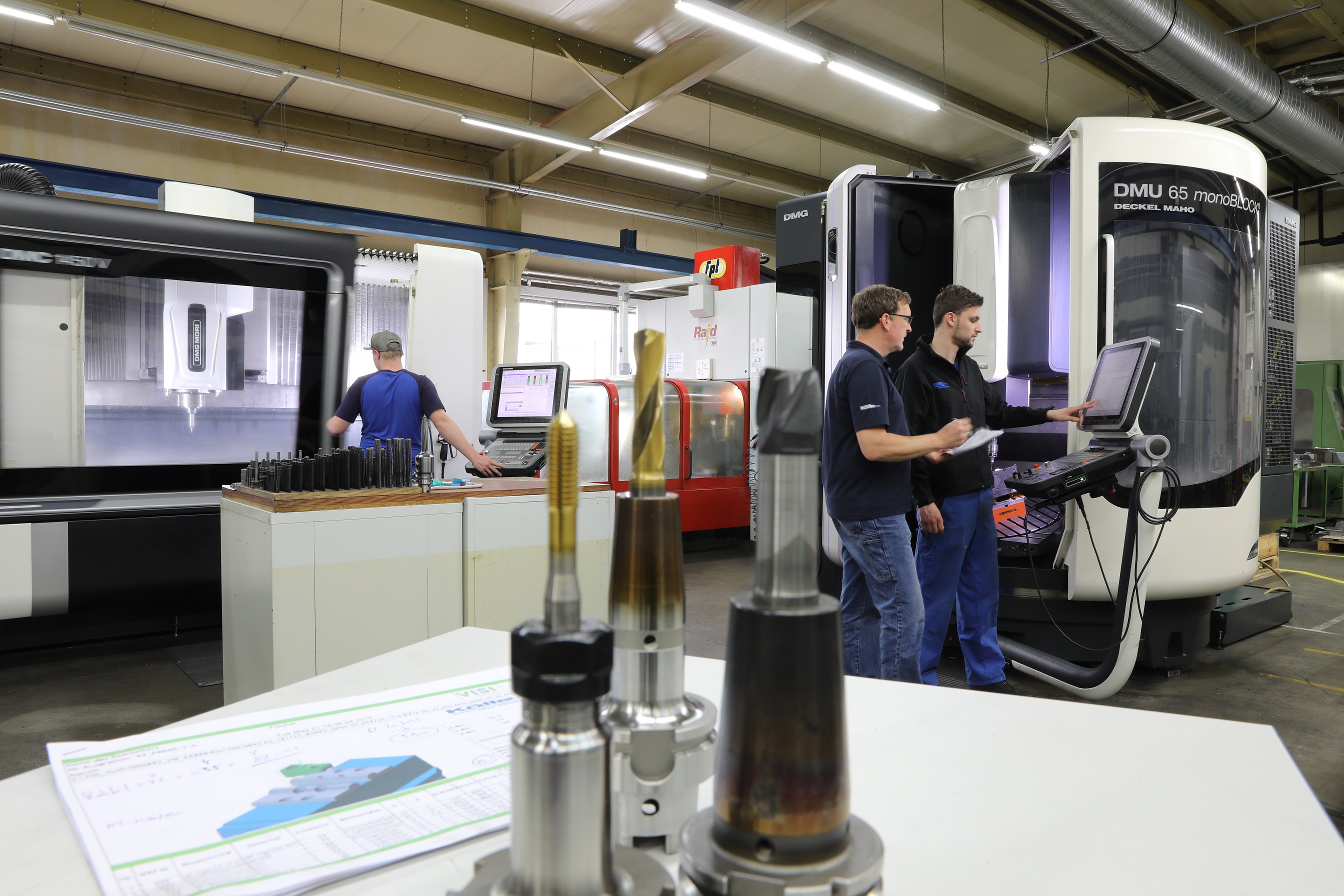

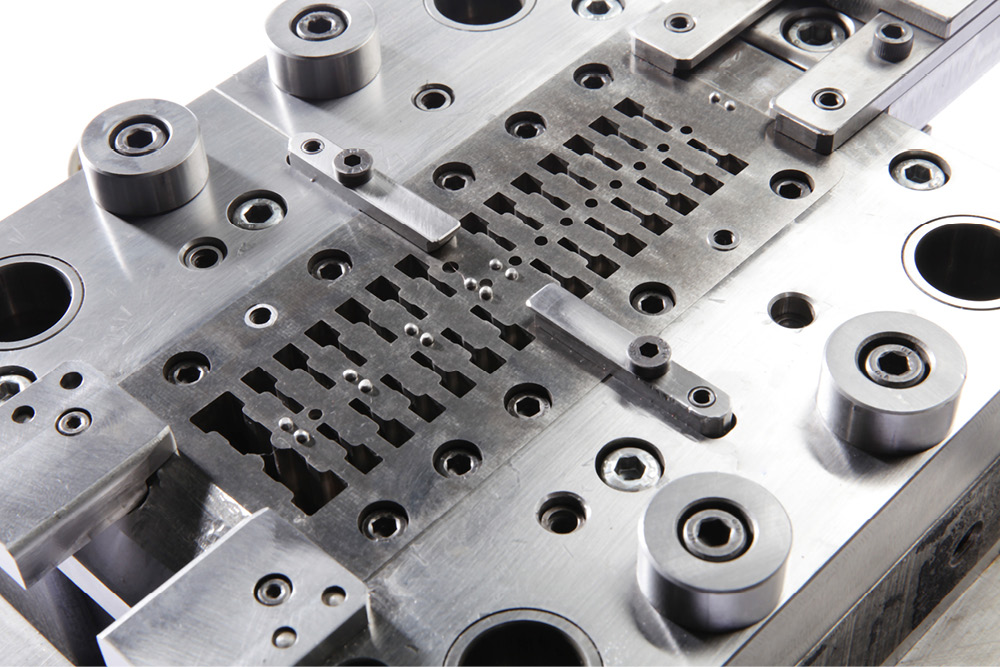

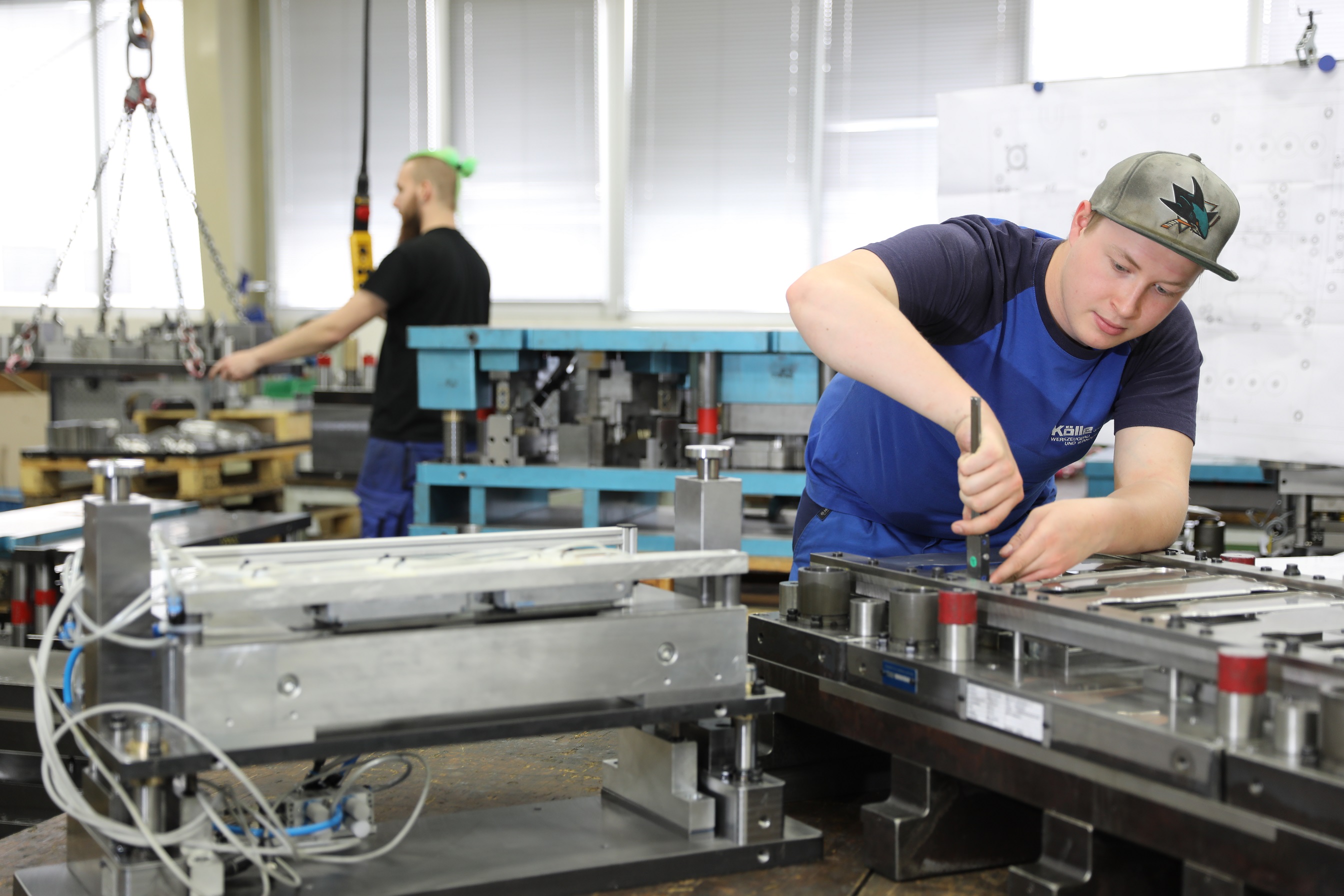

Some of our highly qualified staff members can be found in our stamping department. Here, they produce a variety of advanced stamped, drawn, and bent components made from common materials, e.g., aluminium, steel, and stainless steel, attaining the highest possible degree of quality.

Our large in-house machinery consists of 10 stamping lines with a contact pressure from 400 to 3150 kN. We also employ 7 additional mechanical and 12 hydraulic insertion presses that allow us to complete (almost) any challenge handed to us. We use state-of-the-art process monitoring systems on several stamping lines in order to detect process malfunctions well in advance.

Depending on the specification of our client, we produce prototypes, small batches or offer high-volume production (3 million pieces per year). From our warehouse in Vaihingen, Germany, our logistics department ensures to supply our worldwide customers with their orders at the agreed upon time.